Many companies choose to automate in order to optimize operations, remove waste and use their resources more effectively. At Carolina Handling, we take a consultative approach that focuses on partnership and process improvement. Because we are vendor agnostic, we are able to identify the solutions that best support a customer’s unique challenges rather than forcing a single approach.

We serve as a total solutions partner and a total service provider. As specialists in turnkey solutions for warehouses, distribution centers and manufacturing facilities, we can help customers move material faster and more efficiently by implementing automation equipment and technologies. Most customers do not know exactly what they need, which is why they rely on our expertise to guide them toward the best solution.

Why Automating Key Processes Optimizes Performance and Reduces Costs

Labor shortages, high turnover and rising operational costs, among other things, are driving more companies to explore automation. Automated tools reduce manual, repetitive tasks, which increases efficiency and accuracy while improving safety. These improvements translate directly into reduced operational expenses and increased productivity, particularly in facilities that rely heavily on manual labor.

Order picking remains the most expensive activity in any warehouse. Automation helps address this challenge by improving speed, minimizing error rates and reducing the physical strain associated with traditional order picking tasks.

Common reasons companies choose to automate include:

• Improving processes and labor efficiency

• Improving ergonomics and employee health

• Improving employee retention

• Reducing operational expenses

• Lowering order fulfillment time

• Reducing human error

How Automation Improves Workforce Wellbeing Through Ergonomics and Process Improvement

Automation has become a strategic investment in workforce wellbeing. With labor markets tightening, companies want to attract and retain talent while keeping costs under control. Automation supports these goals by reducing physical exertion and increasing personal safety.

Material handling equipment manufacturers have prioritized ergonomic improvement for years, adding features such as adjustable seats, seat-side hydraulic controls, rear assist grips with horns and tilting steering columns. Automated systems extend these ergonomic benefits further by eliminating high-risk tasks.

Solutions such as conveyors, automated storage and retrieval systems, pallet shuttles and automated guided vehicles help to remove the strain associated with bending, overhead reaching, repetitive motions and lifting, pushing or pulling heavy loads.

Automated mobile robots (AMRs) also reduce the risk of on-the-job accidents. Instead of lifting packages in non-ergonomic positions, employees remain in safe zones while AMRs retrieve products and deliver them to workstations. These mobile robots navigate autonomously, avoiding people and obstacles while determining the most efficient route to their destination. In many cases, AMRs are one of the most effective ways to optimize productivity and enhance workplace safety.

Vertical lift modules (VLMs) also reduce overexertion by bringing stored items directly to the operator at a comfortable height. This eliminates unnecessary walking, reaching, and bending, and can reduce walking time for parts retrieval by up to 90 percent compared to static shelving.

The benefits of automation for employees include:

• Increased ability to meet performance goals

• Improved accuracy with fewer mistakes

• Less physically demanding work

• Increased personal safety

• More engaging and technologically-advanced job tasks

• Stronger demonstration that the company values its workforce

• Opportunities to learn new skill sets

Steps to Automate Warehouse Processes for Better Optimization

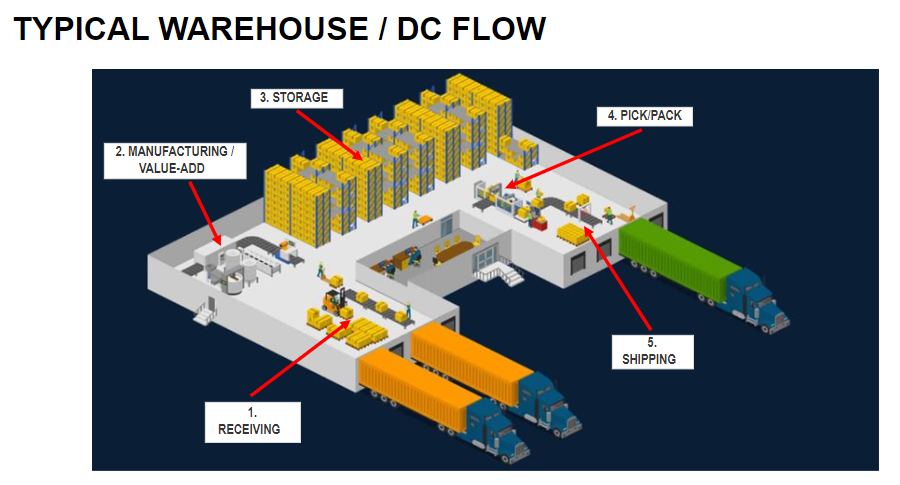

The process to automate typically begins with data collection and discovery. Before recommending solutions, we observe how products move through a facility, from receiving to shipping. We examine current workflows, identify bottlenecks and evaluate existing equipment.

This discovery process helps uncover the root causes of operational challenges, allowing us to design solutions that truly optimize warehouse performance rather than applying isolated fixes.

Why Customized Automation Improves Efficiency and Supports Long Term Optimization

As a systems integrator, Carolina Handling has access to a broad range of automated technologies. Our Intralogistics Solutions Group evaluates operational needs, budget requirements, integration capabilities and growth plans to recommend solutions that align with long term objectives.

Our automation capabilities focus on three primary areas:

- Material Handling and Product Movement

- Storage and Retrieval

- End of Line and Packaging

Automated Material Handling Systems That Improve Workflow and Reduce Manual Labor

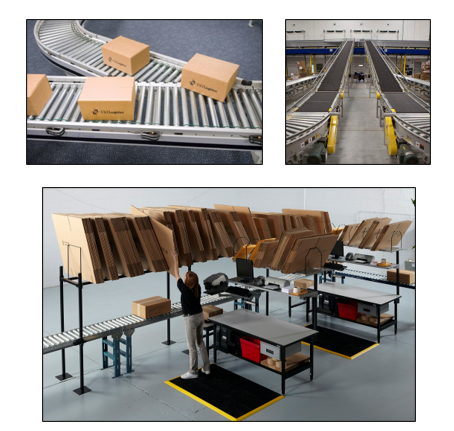

Automated systems that support efficient product flow include conveyor, sortation, robotics and automated trailer loading and unloading.

Conveyor- Applications: Movement of totes, cartons and bags, transporting products between automated processes, ergonomic workstation

- Benefits: Reduced manual handling, smooth transitions, automated vertical movement

- Applications: Sorting inbound and outbound packages, cross deck staging, assembly replenishment

- Benefits: Less manual sorting, consistent decision making, reduced error rates

- Applications: Pallet packing and put away, order picking, assembly and manufacturing

- Benefits: Fewer repetitive labor tasks, smoother workflows

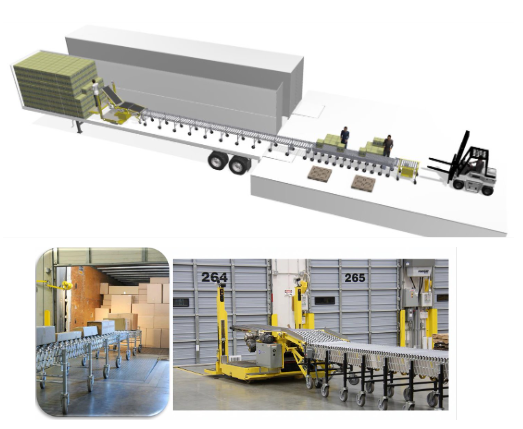

- Applications: Full or partial trailer loading and unloading

- Benefits: Less lifting and bending, improved speed, reduced labor cost per trailer

Automated Storage and Retrieval Solutions That Optimize Space and Accuracy

Automated storage and retrieval systems, including AS/RS racking and vertical lift modules, improve accuracy, reduce pick times and maximize storage capacity.

AS/RS- Applications: Stationary piece picking, order assembly, operations with high SKU counts or inventory volume

- Benefits: High density storage, high selectivity, ability to store full pallets or mini loads, minimal labor, integration with conveyor and mobile robots

- Applications: Pick modules, pick to light, pick to voice

- Benefits: Higher picking accuracy, improved employee efficiency, seamless integration with pick modules or mobile robots

End of Line Automation That Improves Efficiency and Reduces Manual Touches

End of line automation increases production speed by reducing manual involvement in tasks such as case packing, wrapping, palletizing and labeling.

Case Erectors and Case Sealers

- Benefits: Fewer repetitive tasks, improved efficiency, integration with conveyor systems

Pallet Wrapping

- Applications: Orbital and turntable wrappers

- Benefits: Reduced pallet touches, limited operator involvement, integration with conveyor systems

Labeling and Scanning

- Applications: Print and apply label systems, inline scanners and cameras

- Benefits: Fewer manual touches, reduced operator error, improved throughput

Partnering with Carolina Handling connects your operation to a team with nearly six decades of experience. Our experts are committed to delivering measurable improvements in workflow efficiency, workforce safety and operational cost control by implementing tailored automation strategies. From advanced material handling and storage solutions to optimized end-of-line processes, we bring a vendor-agnostic approach, ensuring that every implementation is customized to your facility’s requirements and long-term objectives. Carolina Handling delivers the integrated solutions and industry expertise to help position your operation for long-term success.