North Carolina Conveyor Systems Supplier

Conveyors and automated storage and retrieval systems can increase the efficiency of your distribution facilities, improve safety practices and substantially reduce human resource expenses.

Modern conveyors can transport both individual cartons and entire pallets within your warehouse, and they are an integral component of contemporary material handling design.

Conveyor systems are classified in three separate divisions for most material handling operations:

- Powered roller or belt systems (for package handling)

- Powered roller or chain conveyors (for pallet handling)

- Non-powered conveyor systems

Powered Package Handling Roller or Belt Conveyors

Powered belt or roller systems are generally used for smaller pieces like packages and cartons.

Conveyor belts are usually employed for moving products along a line, while roller systems are used for accumulating packages in certain areas along the line.

Belt Conveyors

In use since the early 1900s, belt systems are a staple of many material handling configurations. Less expensive than roller options and often better suited to specific functions like advancing lightweight products, belt conveyors are used in many material handling configurations.

Conveyor belts utilize a long, looped belt that is positioned on the top of a metal slider belt substructure or an array of non-powered rollers. Motor-driven pulleys turn the belt and move objects down the conveyor line.

Belt systems are configured with a variety of materials and surfaces in accordance with the function and nature of the conveyor. To illustrate, a conveyor belt surface might be totally flat in portions where products need to be pushed off the line and may have a gripping texture on segments where products have to be moved up gradients.

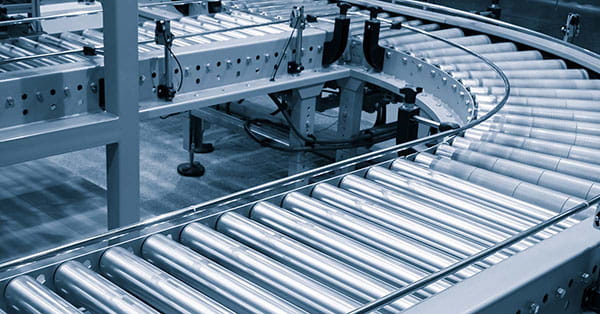

Roller Conveyors

Although belt conveyors are time-tested workhorses, newer roller conveyors feature a host of advantages in many modern material handling uses.

First and foremost, roller configurations can allow for collection of items on the line where belt systems cannot. This is a meaningful contrast because there are endless scenarios where objects must hold and accumulate in material handling applications. Common situations where accumulation is important are when products must be temporarily halted before being relayed to automated palletizers or sorters.

Some roller systems also have the capacity to track products on the line and apply zero pressure accumulation, meaning none of the accumulating objects touch each other as they slow down and finally stop.

Roller designs are made up of numerous cylindrical rollers that are usually powered in one of three different ways:

- Line shaft conveyors: In a line shaft system, a long steel shaft runs beneath the cylinders at a right angle to them and is connected to each cylinder with rubber O-rings. A drive mechanism rotates the shaft and, accordingly, rotates the rollers by way of the connected O-rings. Line shaft conveyors are the most cost-efficient of all roller conveyors, but they can also demand the most repair because the linkages between the shaft and rollers need frequent readjustment and often break.

- Belt-driven roller conveyors: As you may expect, these systems are powered by a belt mechanism that lies underneath the roller surface. A motor propels the belt, which advances the rollers.

- MDR conveyors: Motorized roller conveyors, sometimes called motor-driven roller (MDR) conveyors, are configured in sections where only one roller from each segment is driven by ’its own motor. That one powered roller is linked to the adjacent rollers in that segment by way of rubber O-rings, thereby rotating all the cylinders in the segment. Powered units are placed in sequence to configure the conveyor line.

MDR conveyors are very energy efficient for a couple of reasons: a.) They usually run on 24-volt direct current motors and b.) The motors can be configured to run only when an object is present on the rollers, meaning they are inactive throughout much of the day.

Although the cost of MDR conveyors is higher than belt drive and line shaft systems, power expenses and maintenance outlays are usually quite a bit lower than the other options mentioned. - Segmented belt conveyor: The design of motor-driven roller systems eventually begat the development of segmented belt conveyors. Similar to motor-driven roller systems, segmented belts operate independently and offer a lot of the same benefits of motor-driven rollers, including accumulation capabilities.

Powered Pallet Handling Conveyors

Powered pallet handling conveyors are many times coupled with palletizers and automatic storage and retrieval systems. Pallet handling conveyors can generally accommodate gross weights of up to 4,000 pounds and proceed at a much slower pace than carton handling systems, often at speeds of two to four pallets per minute.

Pallet handling conveyors come in one of two types: chain conveyors and roller conveyors.

- Pallet handling chain conveyor: Perhaps the simplest of all conveyors, pallets on a chain conveyor line are placed directly on two or more lengths of heavy-duty chain. Motors propel the chain segments which consequently move the pallets down the line.

- Pallet handling roller conveyor: Analogous to MDR conveyors, pallet handling roller configurations use large cylinders and sturdy chains to connect the motorized cylinder to the remaining rollers in a conveyor section.

Non-Powered Conveyors

Skatewheel or roller conveyors are the most prevalent types of non-powered conveyors used in typical warehouse operations. Non-powered rollers or skatewheels use inertia and gravity to advance smaller items though pick modules, warehouses, automated sorters, workstations, loading docks and package-sorting areas.

Skatewheel conveyors are made up of numerous separate wheels and need minimal power to prolong the inertia of products as they move down a conveyor line. On the whole, they propel items faster than non-powered roller systems, and they have more versatility when it comes to setup. Given that they’re separate wheels instead of a belt, they are often applied in curvilinear segments of a conveyor system.

In general, non-powered roller systems are less expensive than skatewheel conveyor systems. They’re frequently used for workstations, pick modules and other sectors where it’s beneficial to have a level platform to perform tasks. Roller systems may also be utilized to slow products down that originate from faster moving systems like sorters so that employees can keep pace with system output.

Non-powered skatewheel and roller systems have a distinct liability in comparison to powered conveyors: By applying gravity and inertia to move items you can’t regulate, the force applied to those materials. Simply put, you don’t have control of the inertia and speed of materials on your line.

Conveyor Companies Near Me

If you’d like a complete evaluation of conveyor system options for your warehouse, distribution center or other material handling operation, speak with an expert at Carolina Handling.

-

-

Proudly serving

Greensboro,

High Point, Kernersville,

Winston-Salem,

Clemmons, Burlington,

Salisbury, Rural Hall,

Thomasville,

and the entire

State of North Carolina.

You May Also Like:

Automation

Carolina Handling can help you automate every aspect of your warehouse operation to increase efficiency.

Learn More

Optimization

Optimize everything in your warehouse to improve productivity and reduce operating costs.

Learn More

Warehouse Products

Looking for the right product for your operation? We have everything you need to do business in stock.

Learn More

Service Maintenance

Providing superior lift truck service and maintenance for our customers is Carolina Handling's highest priority.

Learn More