Case Study: Premier Yarns' Pick-Pack-Ship Solution

-

Premier Yarns needed to improve the speed and accuracy of its pick, pack and ship operations. Carolina Handling's integrated solution has helped double daily picks and significantly improve fulfillment times for the manufacturer and distributor of hand knitting yarns.

-

OVERVIEW

-

WHO:

Premier Yarns

INDUSTRY:

E-Commerce

NEEDS:

Improve speed and accuracy of pick, pack and ship operations.

SOLUTION:

Integrated automation system featuring ground-level and elevated conveyor, spiral turn and mobile robotics.

RESULTS:

Doubled daily picks. Reduced fulfillment cycle.

-

Pack and ship operations previously were housed together in a back corner of the warehouse.

-

Locus mobile robots deliver orders to induction where they are checked, packed and labeled at new packing stations, then placed on the conveyor for delivery to shipping.

-

A motor-driven roller (MDR) spiral turn lifts packages to an overhead conveyor that delivers them to shipping.

-

Mobile robots have doubled picking speed to 1,000 orders per day.

-

Screens attached to mobile robots identify picking location and quantity to be picked.

-

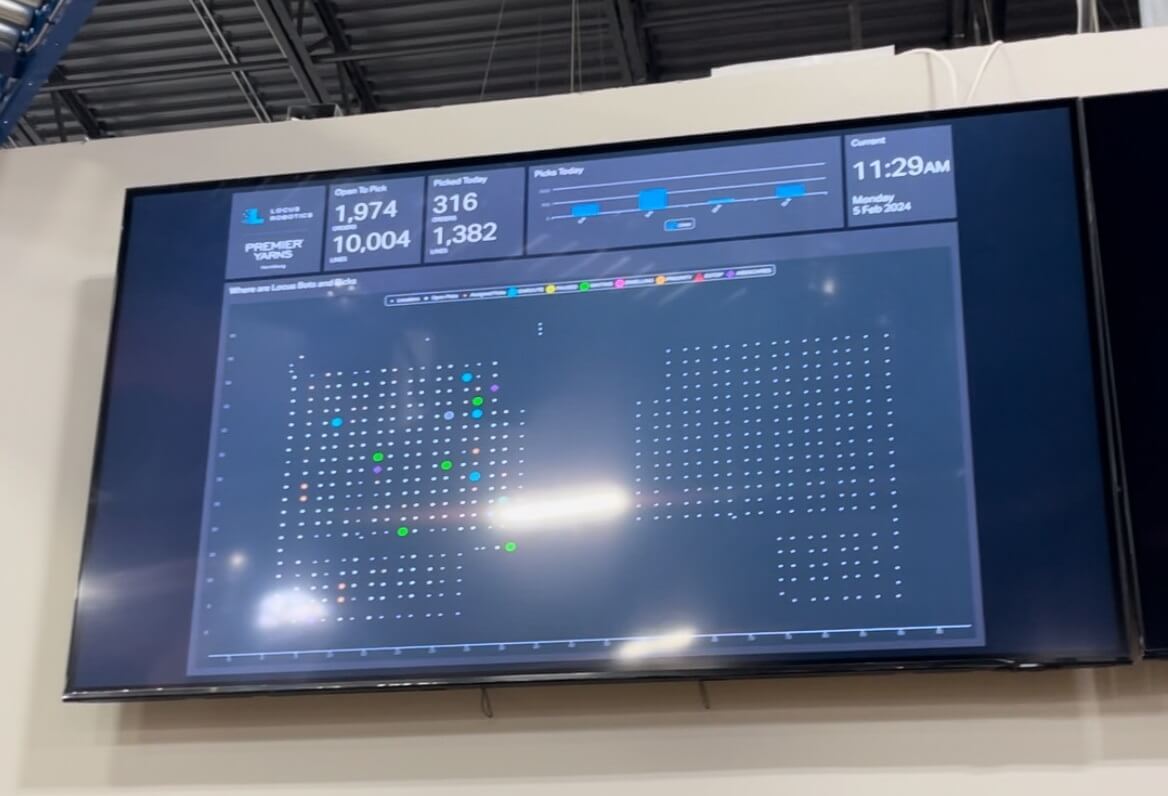

Monitors show real-time locations of picks.

Stay In Touch

-

HISTORY OF PREMIER YARNS

Knitting, quilting and other crafts experienced a revival during the Covid-19 pandemic with companies like Premier® Yarns in Harrisburg, North Carolina, seeing a spike in sales as those quarantined at home turned to a mid-19th century pastime to pass the time.

A leading North American manufacturer and distributor of hand knitting yarns, Premier opened as a mass market distributor in 2005, selling its colorful skeins to retail chains like Walmart, Hobby Lobby, JoAnn’s and Michael’s, with a sister company, Universal Yarns, selling to smaller, independent retailers.

The company launched a website in 2008 and, in 2010, established an e-commerce platform for online sales to end users. Before the pandemic, sales online had slowly increased from an average of five orders per day to about 20. But when Covid forced retailers such as JoAnn’s and Michael’s to close, Premier’s online orders immediately jumped to 400–500 per day.

“In 2022, on Black Friday, we got slammed with orders on our dot.com business,” said Premier Yarns President Hal Ozbelli. “FedEx was coming three times each day for pickup, and we regularly ran out of supplies like boxes and tape.”

As orders continued to pour in, Premier owners knew they needed an alternative to their largely manual process.

“We needed to pick fast and accurately,” said Premier Managing Director Yonca Ozbelli. “We considered outsourcing to a third-party logistics company, but quality control is a main issue for us.”

Instead, Premier turned to long-time material handling partner, Carolina Handling.

"After we visited a few of the companies that are currently using these systems, it was a no-brainer. We have found the right partner and team to work with,” Hal Ozbelli said.

-

CONSIDERATIONS AND GOALS

Premier’s primary goal was finding a solution that would improve the speed and accuracy of its pick, pack and ship operations. With online orders continuing to grow post Covid, fulfillment rates of 10 or more business days needed to be reduced to a 2- to 3-day turnaround.

Additionally, the company needed a system that would work within its existing 60,000-square-foot facility and an installation that would not disrupt operations that already were strained.

A final consideration was maintaining sound quality within the facility.

“When we first came in, we noticed that all of their processes were very manual,” said Carolina Handling Systems Engineer Jacob Barrett. “At Premier, you’ve got to pick, pack and ship, and there wasn’t one solution for all of those, so we looked at ways to add both mobile robotics, as well as conveyor and sortation solutions to their current process.”

-

BEFORE: Design engineers took advantage of underutilized floor space in the middle of the Premier Yarns warehouse to install a conveyor with packing stations on either side.

-

AN INTEGRATED SOLUTION

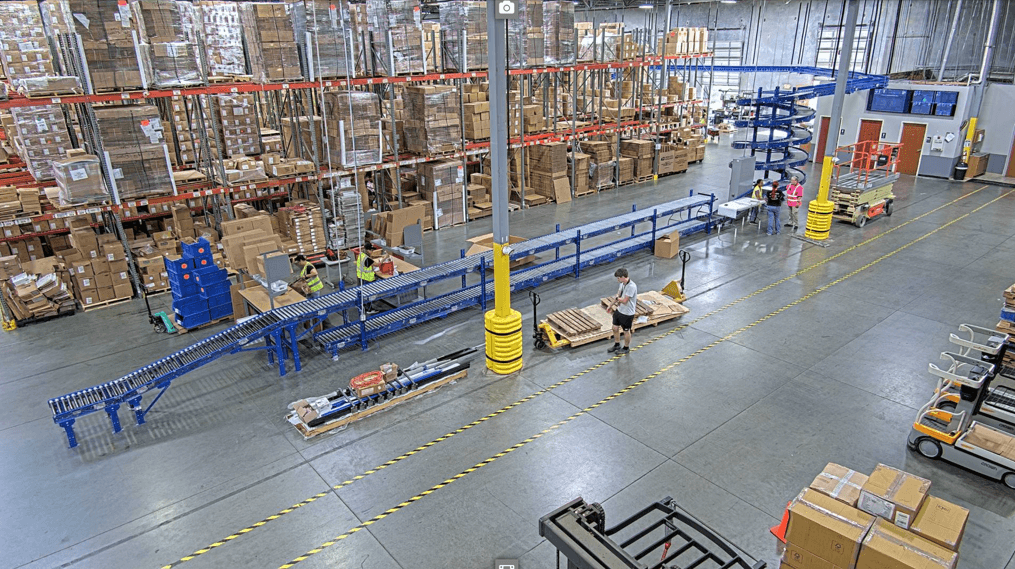

Taking advantage of underutilized floor space at ground level and high warehouse ceilings, Carolina Handling’s Intralogistics Solutions Group first installed a conveyor to serve as a highway for delivering picked orders from packing stations at the center of the warehouse to shipping stations near the back of the facility..

With the new system, 12 mobile Locus robots deliver picked orders to an induction area where they are placed onto a top conveyor and delivered to packing stations on each side.

Once orders are checked, packed and labeled, corrugated cartons and plastic totes are placed on a bottom conveyor, which elevates them through a motor driven roller (MDR) spiral turn, then moves them vertically across the warehouse via a ceiling-hung conveyor. The conveyor declines to the shipping area where packages are offloaded, metered and sorted by shipping method.

Conveyors are equipped with rollers that are sensor activated when a carton or tote approaches. As products pass, rollers turn off until another package is detected, keeping noise levels low and energy efficiency high.

-

AFTER: A new conveyor takes orders from packing stations to an MDR spiral turn which lifts them to an overhead conveyor and delivers them across the warehouse to shipping.

-

SHORT- AND LONG-TERM BENEFITS

Premier Yarns already has seen a return on investment, doubling its daily shipments to an average of 1,000 per day, according to Warehouse Manager Marsha Sanders.

“Our daily picks have doubled, and we’ve gone from a huge window time frame of shipping our orders–5 to 10 business days down to 2 to 3 business days. “We’ve seen that transition happen pretty quickly,” Sanders said.

Pick accuracy has also improved, along with employee satisfaction.

“It helps with mispicks because our robots distinguish which items to put in the totes,” Sanders said. “It’s also a lot less physical because our pickers are assigned to designated aisles, and they now are hands-free. They aren’t pushing around carts; so with the flow, they’re able to replenish, work and clean the aisles as they’re going without anything in their way.”

The automated system also assists with replenishing and planning, Sanders said.

“We’re able to assess our open picks from the TV screens (at right) provided to us by Locus, so we’re able to see where all our line picks are daily–how many robots are in those areas, how many quick picks (five lines or less) we have,” Sanders said. “If we see there are a lot of picks in a certain area, we know we need to focus on those aisles and make sure they’re staying replenished and always have stock so our bots can go.”

-

ROOM TO GROW

Fast and accurate fulfillment of orders has given Premier Yarns a newfound flexibility to run promotions and release new products.

“We are no longer time constrained about releasing new products and how that might hinder our picking time or add a burden to the team,” Yonca Ozbelli said.

It also has owners considering additional robots and additional employees.

“Because our business is growing because of our better, faster service to our customers, we see that orders are coming even stronger, so we’re keeping all of our employees and even adding more team members to help us with the growth and replenishment of our product on a daily basis,” Hal Ozbelli said.

“I’m hoping to get more robots from Locus, and I’m hoping to add another line to the conveyor where we can separate the way orders are being sent out. We’re looking for a robust 2024 for our company.”

Download Printable Case Study