A Best Practices Guide To Forklift Safety In The Warehouse

- share

Forklifts are likely an integral part of your warehouse operations. So are the people who operate them.

Learn why forklift safety is so important, and find tips to help your facility stay accident and injury free.

The Facts on Forklifts

While we all do our best to promote the safe use of forklifts, accidents do happen. Over 100,000 accidents occur each year, 34,000 of which involve serious injuries. And nearly 100 workers are killed each year in forklift-related accidents, with roughly a quarter of these accidents being rollovers.

The good news is that manufacturers have improved forklift design and safety dramatically over the past few years. But there are still best practices you can follow to protect your employees and further prevent accidents and injuries.

Best Practices for Forklift Safety

Forklift safety requires a multifaceted approach. We recommend focusing on these three key areas:

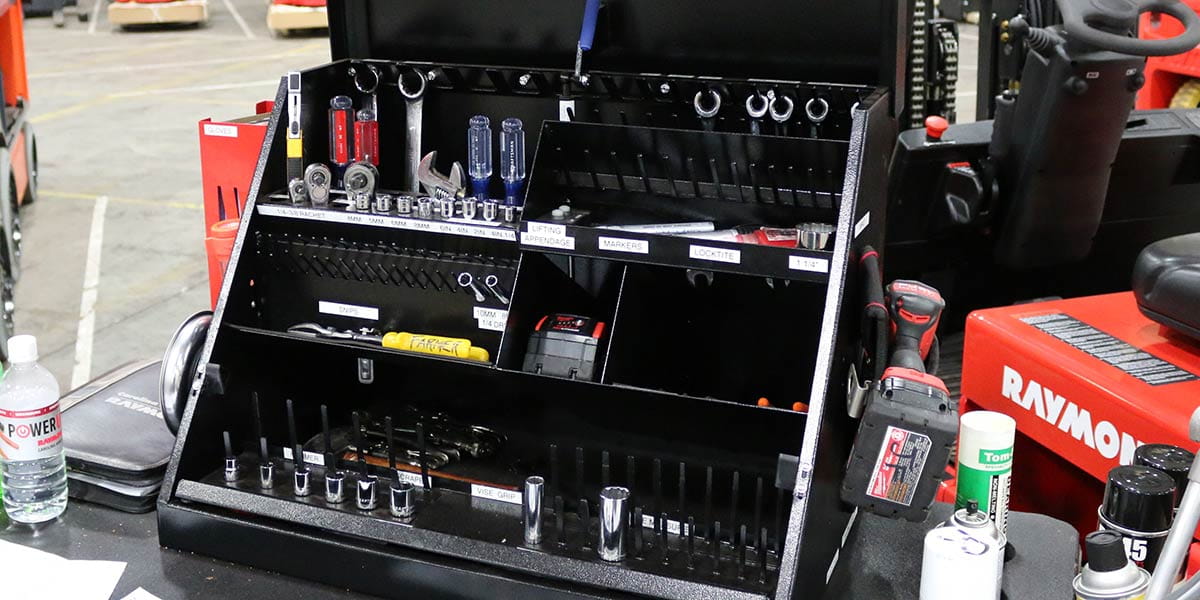

Maintenance

Follow the manufacturer’s service schedule. This is typically every 90 days or 100 hours. Keeping parts regularly serviced and updated helps keep your trucks running efficiently. It also helps minimize the possibility of a malfunction that could unexpectedly cause problems for your drivers.

The condition of your facility plays an equally important role in forklift safety. Follow these tips to help you create a safe warehouse environment:

- Try to segregate pedestrians and trucks as much as possible. Make sure any crossing areas are clearly marked.

- Clear aisles (and all areas) of debris and obstacles. Wide, one-way aisles are ideal.

- Clean up any spills or wet/slick spots that could cause slipping or skidding.

- Enforce a speed limit. Consider installing wall-mounted mirrors to help with visibility.

- Minimize the need for reversing and ramp use where you can.

- Make sure your facility is well ventilated and well lit.

- Designate separate spaces for truck parking and maintenance.

This is perhaps the most important area of focus. In fact, OSHA mandates that employers provide forklift operators with training for vehicle inspection and maintenance.

- Here some best practices for keeping your operators educated and safe:

- Hire forklift drivers who are at least 18 years of age or older.

- Provide a detailed training program for new drivers, and repeat the training for all drivers annually.

- Ensure drivers use seat restraints. They can be the difference between life and death if a major accident occurs.

- Make sure drivers are aware of weight limitations for each truck, and that they adhere to them.

- Create a checklist for drivers to inspect their truck. Inspections should be conducted daily, or after every shift. Check for things like:

- Tire condition

- Functionality of gauges, guards, mirrors, alarms, and blinkers

- Fuel and battery levels

- Fluid levels, power steering, and condition of hoses

Need help with your forklift safety program?

Carolina Handling provides safety training and classes for your entire operation, including OSHA-compliant operator training led by Raymond-certified instructors. Contact us to learn more.